POLYETHYLENE PIPE SYSTEMS

FCS supplies pipes produced from polyethylene raw materials of different densities (LDPE, MDPE, HDPE) for various purposes, manufactured according to TSE, DIN, ISO, and other international standards. FCS can provide pipes with diameters ranging from 20 mm to 125 mm in coil form (or in 6 and 12 meter straight lengths upon request), and pipes with diameters from 125 mm to 800 mm in 6 and 12 meter lengths. The high impact resistance, flexibility, and high elongation coefficient of polyethylene pipes make them suitable for safe use in rocky terrains, landslide areas, underwater, and especially in regions with frequent ground movements.

PE 100 Coil Pipes:

PE 100 pipes are supplied in the form of coil or as straight pipes. PE 100 pipes can be bent 360° with certain radius without using elbows depending on the mechanical properties of the raw material. Due to this feature, the radius of the coil must be 18-35 times the diameter of the pipe. The number of end-tying is reduced in coil pipes, the projects are completed with the increase in installation speed, and the installation workmanship, transportation and storage costs decrease.

PE 100 Pipes-Area Of Use

-Underground and surface watersupply networks

-Sea discharge systems

-Sewerage discharge systems

-Waste Water System

-Solid waste drainage system

-Agricultural irrigation systems

-Irrigation of garden and sport area

-Geothermal system and mining

-Pharmaceutical and chemical industries

- Cement industry -Petrochemical industry

-Food sector

-Fisher industry and marina - In buildings and many industrial system

-Fire water and cooling water system

-Telecommunication cable system

-And many others applications.

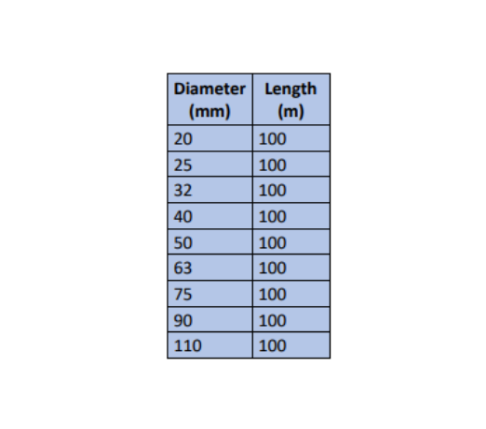

Coil Pipe Lengths

Advantages of Polyethylene Pipes

-Resistant to chemicals, corrosion, decay and wear. Minimum service life: 50 years..

-Due to the high flexibility they can be joined outside the trench. Resistant to ground movements. Can be safely used in areas with uneven and moving grounds such as streams, rivers, lakes, mining areas etc.

-As they can be bent with a radius 20-40 times the diameter at pipe bending points at 20C" depending on the wall thickness, they save cost and time with less elbow usage.

-They adapt to terran conditions in the laying process, and provide advantage with less filing material and installation without wastage

-Thanks to their efficient joining methods (butt welding, electrofusion, coupling, flange, slip socket etc), they will not come apart or break at the joints under pressure, and they provide 100% sealing.

-As there is no molecule immigration to the liquid in concem, they do not change the taste and smell of water. They do not gather dirt or moss, and do not generate bacteria. As they do not contain any toxic substance they may come into contact with food as approved by the Ministry of Health.

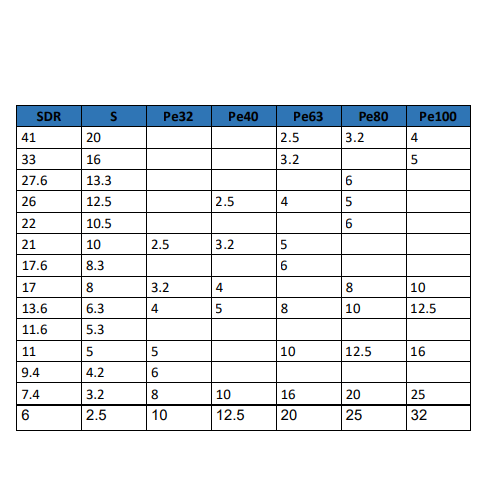

PE PIPES AT 20°C SDR, S, AND PN VALUES

PN (Bar - Atü) Material Class

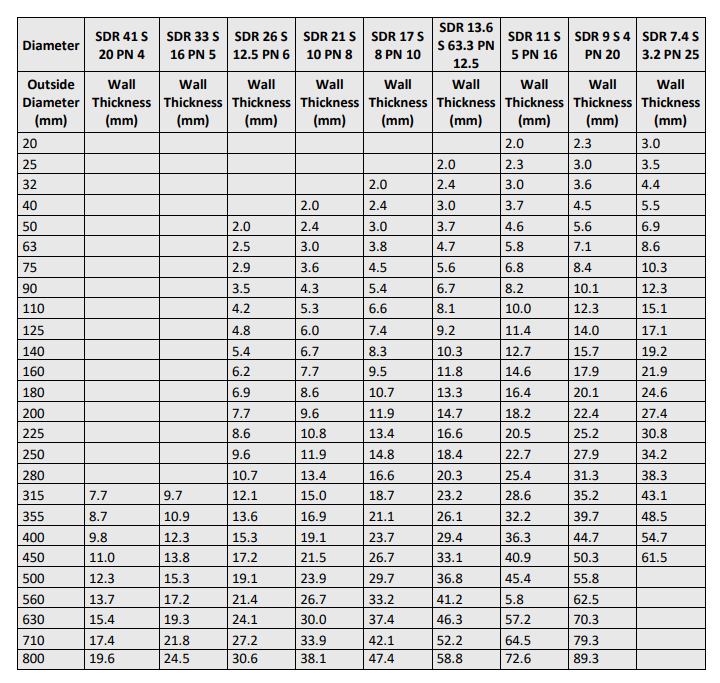

PE 100 Polyethylene Pipes

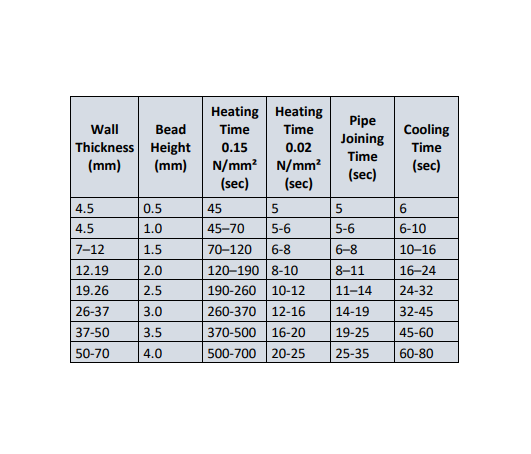

HDPE Pipes Optimum Welding Times