GRP Pipe (Glass Reinforced Plastic Pipe)

Features

Since the pipe is made of fiberglass reinforced plastic, it does not corrode. It is highly resistant to chemicals. The pipe connection parts are resistant to chemicals, and the sleeve connections have elastomeric sealing gaskets. It is lightweight (1/4 the weight of steel pipes, 1/10 the weight of concrete pipes). Long pipe sections. It has an excellent smooth inner surface. The physical properties of the pipe comply with international standards.

Advantages

-Its economic lifespan is at least 50 years. It does not require expensive cathodic protection or internalexternal coatings. There are no maintenance costs. Lime scaling is minimal.

-It is easy to connect – saves time. It does not get damaged under pressure or sudden discharges. It is suitable for angular direction changes without the need for additional parts or fittings.

-It is installed quickly and easily. No heavy equipment is needed for transporting the pipes. Transportation costs are low.

-There are very few joints, requiring only a small number of seals. Very fast installation and laying are possible.

-Friction loss is low. Due to the high Hazen-Williams coefficient, it requires less pumping energy.

-It is a high-quality product based on advanced technology.

Product Range

Lengths: 0.3 m to 15 m

Pipe Diameters (DN): 300 mm to 4200 mm

Pressure Classes (PN): 1 bar to 40 bar

Stiffness Classes (SN): 2500 N/m² to 10000 N/m²

Applications

-Buried underground

-Laid underwater

-Mounted above ground

-In potable water main transmission lines and distribution networks

-In pressurized and non-pressurized wastewater pipelines

-In rainwater drainage systems

-In closed-loop irrigation systems

-In cooling water lines of power plants

-In industrial cooling water pipelines

These are widely used in various applications.

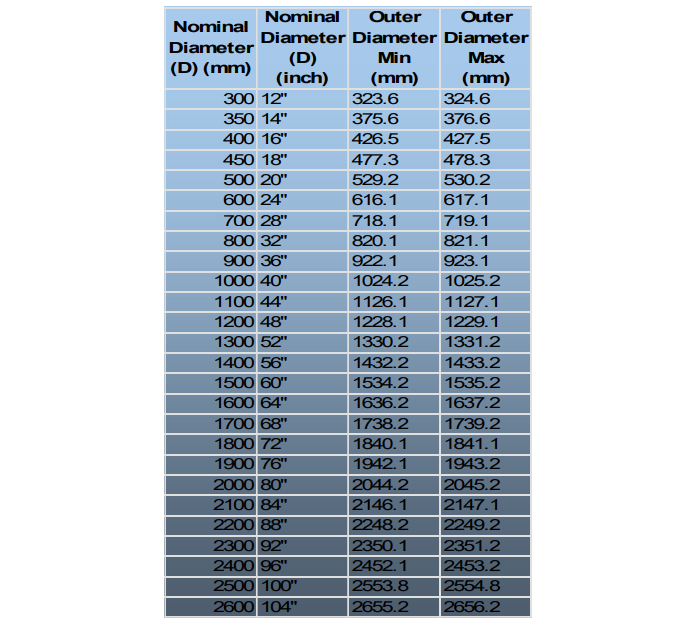

GRP pipe diameters

FCS GRP pipes and fittings are manufactured in standard sizes ranging from 300 mm to 2,600 mm. The standard pipe diameters are provided in the table below.